Wait a couple of seconds until translation has finished until last page, then press print button to print or create a pdf file from latest XCVario documentation

Inhaltsverzeichnis

- 1. Introduction

- 2. Features

- 3. Overview

- 4. Operation

- 5. Device Management

- 6. FLARM

- 7. Configurations and Router

- 8. Basic Setup

- 9. Vario and Speed 2 Fly

- 10. Audio

- 11. Glider Details

- 12. Options

- 13. Units

- 14. Flap (WK) Indicator

- 15. FLARM

- 16. Compass/Wind

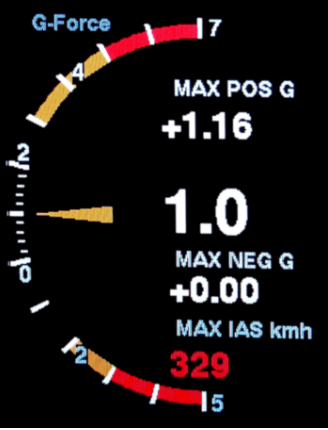

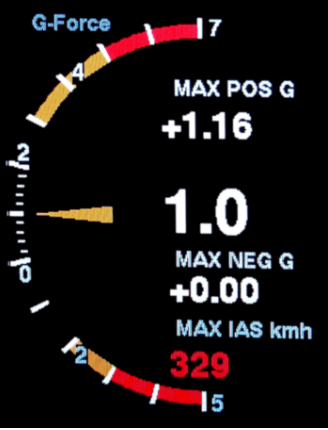

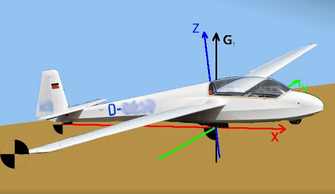

- 17. Wireless

- 18. G-Load Display

- 19. System

- 20. Software Update

- 21. Battery Setup

- 22. Hardware Setup

- 23. Altimeter, Airspeed

- 24. Serial Interfaces

- 25. NMEA Protcols

- 26. Logging

- 27. XCSoar

- 28. Installation

- 29. Technical Specification

- 30. Maintenance

- 31. Warranty Policy

- 32. Permit

- 33. Limitation of Liability

Introduction

XCVario User Manual

XCVario 57mm and 80mm

Series: All

Software Version: Latest

Manual edition 3.04

info@xcvario.de

Other versions of earlier software statuses at: https://github.com/iltis42/XCVario/tree/master/handbook

General

The XCVario is a modern digital and smart variometer with wired serial and wireless interfaces to any navigation display or with applications such as XCSoar, LK8000 and more, as well as wired interfaces to a GPS source, a FLARM, an OpenVario or other devices. It has modern, high-resolution digital sensors for pressure, acceleration and temperature, an expansion tank as is usual with older systems is no longer required.

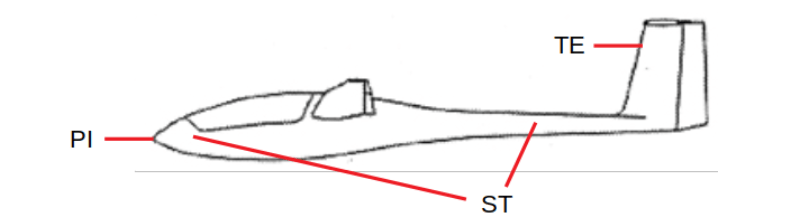

The XCVario is connected to the TE nozzle pressure, the static and the dynamic pressure, and compensated either conventionally via the TE nozzle or electronically. It has an audio function via its own built-in 2 watt speaker.

The forward-thinking Kalman filter offers a quick response to changes with good smoothing of the vario display, without the usual delay of a few seconds, which is known from simple damping. The Vario shows exactly what you feel. The Vario can also be adjusted according to personal preferences via the setup with many setting options.

From the 2021 series, the load factor (n) is taken into account when calculating the current sink value from the polar coefficient using an acceleration sensor, because the increased load factor requires more lift from the profile with the same aircraft mass (difference to higher ballast). This increases the drag coefficient and this leads to increased sink rates. In a standard class aircraft, for example, with a load factor of 2 g, this results in about twice the sink rate. This is not insignificant and is taken into account in the net vario, which significantly improves the net vario display, especially in the case of dynamic processes (pull up, push down) compared to conventional devices without the corresponding sensors.

Optionally, a FLARM or another source for NMEA (GPS) data can be connected to the XCVario, the Vario not only forwards this data to XCSoar, tasks can also be declared on an (IGC) FLARM with XCSoar, settings made and the flight can then be read out. Clubs can operate the device with its many options in the “Student Mode”, which allows users to only modify the 5 most important settings such as QNH, MC, etc.

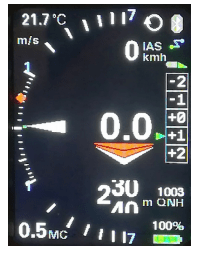

The standard installed and freely available software of the XCVario (https://github.com/iltis42/XCVario) offers many features. In addition to a vario display, speed with MacCready setting, there is a precise altimeter, a wind indicator, a charge level indicator for the battery, a temperature indicator and more. The flap display, which can be switched on as an option, can display the flap position using an external sensor and provides information on the optimal flap position depending on the wing loading, the speed and the load factor. Thanks to a growing library of more than 100 polars for a wide variety of glider types, the vario can be adapted to almost any glider. Since the software is publicly available on github, developers can clone the software and further develop their own features and ideas, and also deliver them.

In addition to the independent function, the Vario can exchange data with the software running there via the wireless interface either via Bluetooth or wireless LAN (WLAN, WiFi), or via the RS232 (-TTL) interface, depending on which interface the device used has . The wireless standards ensure secure and stable transmission and have the advantage that there is no need for hardware-related and sometimes complex cabling with the navigation device.

Thanks to the high resolution of the digital, temperature-compensated and factory-calibrated pressure sensors, even the smallest height differences of just 8 cm are detected. Properties such as accuracy, reliability and long-term stability are therefore given. The sensor for the dynamic pressure or speed or IAS enables an absolute accuracy of better than 1%, at 100 km/h the deviation is a maximum of 1 km/h.

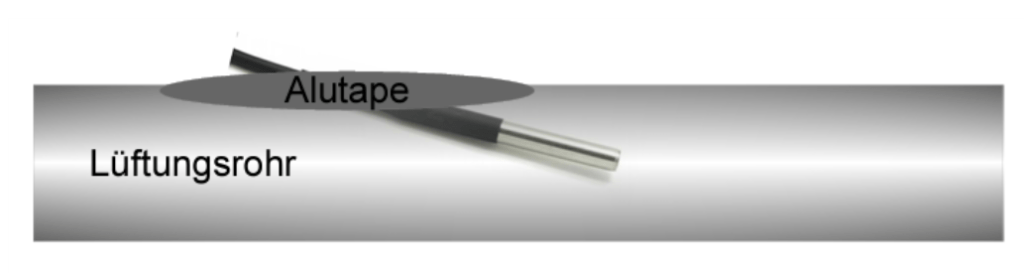

The outside temperature can be measured with the digital temperature sensor in the ventilation area to 0.5° Celsius with a resolution of 0.1° Celsius, and is included in the calculation of the TAS (True Airspeed) as an atmospheric parameter for determining the air density.

The exact flight speed, as well as the temperature and TE vario values, can be used to calculate precise values for the target flight. The precise altimeter without hysteresis allows final approach altitudes to be calculated appropriately in XCSoar, because the wind calculation in XCSoar and now also in the XCVario itself works reliably and precisely together with a GPS source.

It is very easy to operate and is done using the rotary (rotary knob) with Push&Turn (press and turn), next to it there is a button to switch it on. The system, which is manufactured in large numbers, is an excellent replacement for old vario systems with many additional modern features.

Features

- Airliner-style bar display or retro-style pointer display

- TE variometer with optimized Kalman filter, adjustable range and damping

- Barometric altimeter with QNH setting or QNH autosetup (airfield altitude as default)

- Speed display (IAS or TAS) with speed command (S2F)

- Adjustable wing loading and MacCready value

- Built-in speaker with volume control, power 3 watts

- Sound individually configurable (height, chopping, dual tone, deadband

- Flaps display with optimal position according to ballast, airspeed and the load factor

- Extensive polar library with over 100 common polars

- Polar can be modified later

- Digital compass with external magnetic sensor (21 series)

- Wind calculation in circular flight and with compass also straight flight (TAWK method, in development)

- MacCready, ballast and bugs setting option

- stall warning

- Outside temperature display with external sensor

- Battery charge status display, voltages configurable

- Wireless Bluetooth V4.2 (classic BT) or standard WLAN access point for external devices

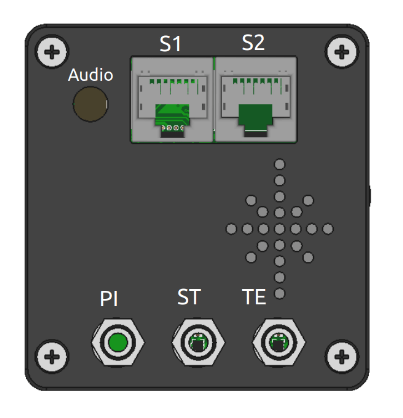

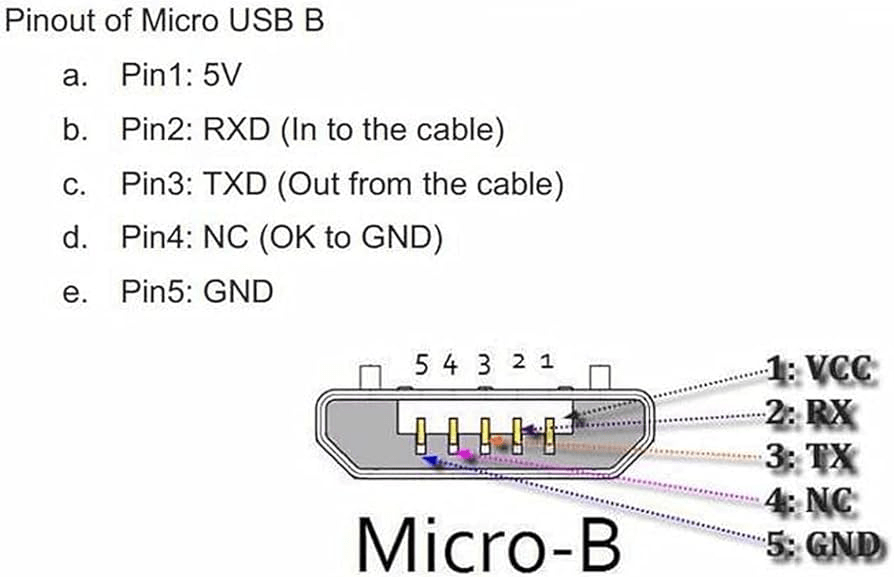

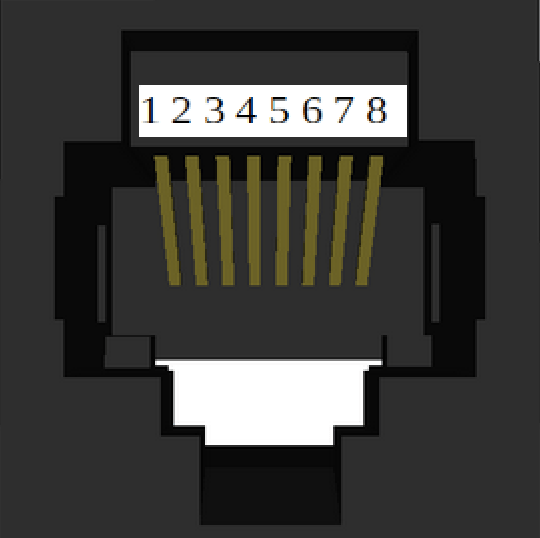

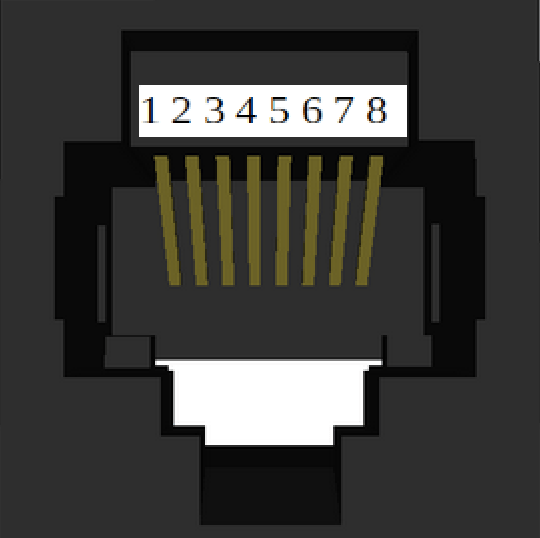

- 2x RS232 TTL interfaces, S1 with standard cable in IGC standard, S2 socket in IGC standard

- High accuracy barometric altimeter

- Sunlight readable, bright and high-contrast 2.4 inch IPS display with 57 mm diagonal

- Switch input for vario/set speed changeover (switch or button adjustable)

- Simple setup menu using rotary switch with push and turn function

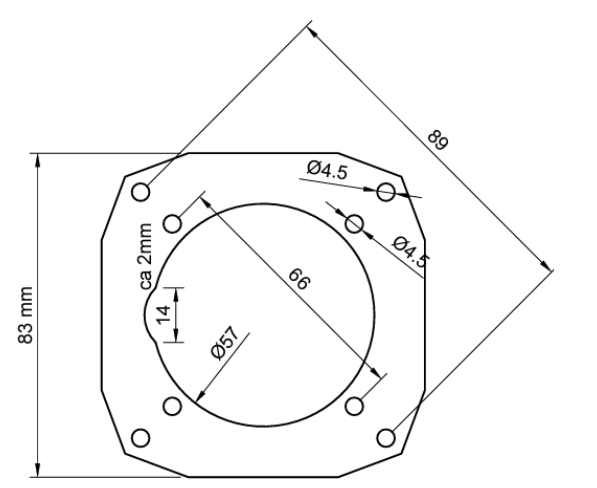

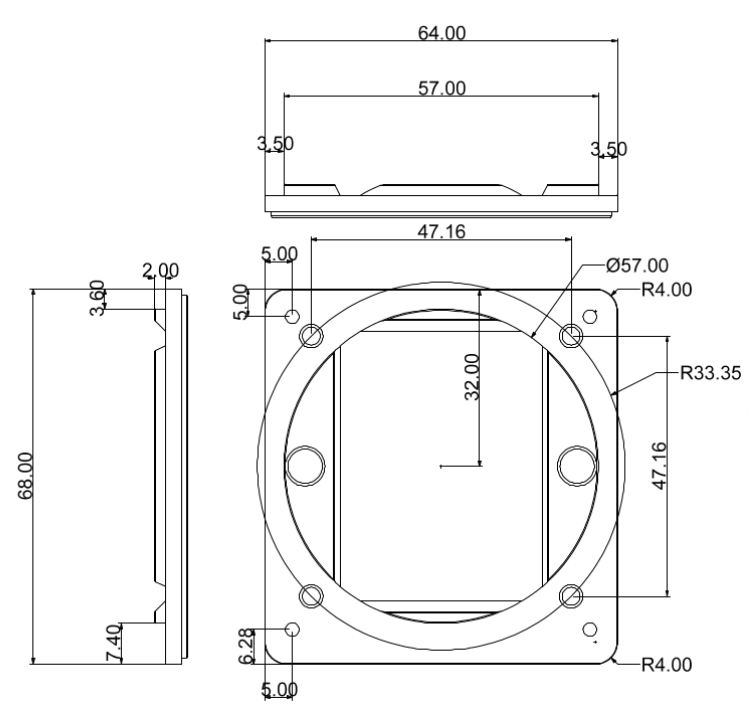

- Light and small device avail for standard 57 mm instrument cut-outs, housing depth only 35 mm

- Elegant and robust CNC milled mat black anodized aluminum housing (shielding, low EMI)

- Software update via WiFi ‘Over The Air’ (OTA) when installed for new feature

- Analog input for flap display

- As an alternative to the flap display, landing gear warning via the same input

- Full FLARM Bridge for task declaration in IGC Flarm, flight download and FLARM setup

From the hardware 2021 series, the following 3 new hardware features have been added:

- Audio power now 2 watts, better sound at high volumes

- Second serial RS232 TTL interface S2, IGC standard assignment and DTE and DCE support (RX/TX pins exchangeable via software)

- Input e.g. for a flap sensor or an undercarriage warning

- Optional feature: Attitude and Heading Reference System (AHRS): 6-axis direction and attitude sensor with 3-axis gyroscope and 3-axis accelerometer

From hardware series 2022:

- In addition, a CAN bus interface on S2 for connecting a second two seater device, a CAN magnet sensor (from October 2022), as well as future extensions.

From hardware series 2023:

- Temperature control for the AHRS chip for improved long-term stability

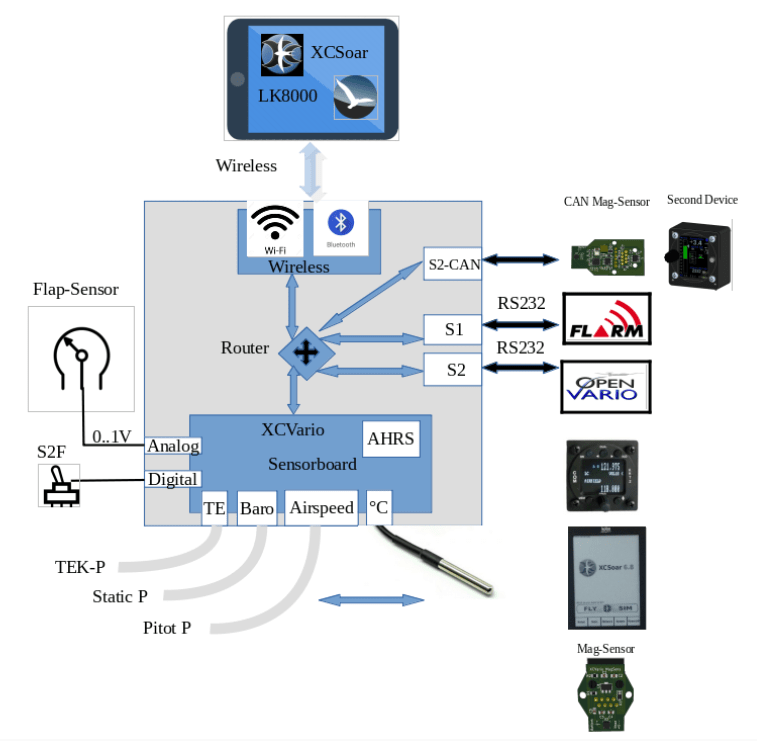

Overview

The following overview shows the embedding of the XCVario in the cockpit environment.

The standard case and most common case is the connection of an Android device with XCSoar to the wireless interface with Bluetooth, as well as a FLARM with the appropriate cable to interface S1.

For this purpose, the interface S1 is connected to the wireless interface. This is the delivery state of the settings.

With the WiFi standard on the wireless interface, it is also possible with devices from the 2021 series to control another device, e.g. a radio device on the S2 interface. More on this in the XCSoar Setup chapter.

Operation

The operation of the XCVario is very simple and intuitive, and takes place via a rotary knob (rotary) with button function (push and turn), an optional additional switch or button (configurable) for Vario or speed command mode, and via the on-off switch. The following description applies to the default setting, the function of the rotary can be set, more on this in the chapter on setup.

After switching on on the ground, the QNH must first be set on the rotary knob, or confirmed if the elevation (height of the airfield) is configured. After pressing the rotary knob, the display and the data transmission of the device go into operation. Turning it to the left decreases the volume, while turning it to the right increases it.

During operation, the menu for the parameters such as MC value, ballast, polar and more is started after pressing a button (push).

A simple push takes you to the top point of the setup [<<Setup], which offers a return from the setup without turning, i.e. scrolling in the menu. Another push without scrolling switches back and forth between setup and normal operation. In the setup menu there is a help text for almost all functions so that the correct settings can be found quickly even with little practice.

By turning the rotary to the right, corresponding to “scroll down”, or to the left for “scroll up”, the individual sub-items are selected in the setup.

Most of the items in the setup menu return to the top item of the previous level, allowing multiple settings to be made without exiting the menu entirely.

The setup menu is nested, you can descend further into the individual items by pressing a button (push), the top item returns to the previous menu.

All setting values can be decreased by turning to the left and increased by turning to the right.

If you want to save the value, you can acknowledge this with a simple push, the saving is confirmed and you return from the dialog.

Dialogs for parameters that are usually set separately, such as the MC value, return directly to the vario display. This saves you having to press another button to exit the setup.

The XCVario can also be remotely controlled via software commands, supported is rotary operation such as short or long press to change the screen, for example, or to go to the setup, scrolling (up/down) for the menu navigation, as well as some shortcuts for changes in volume or MacCready value.

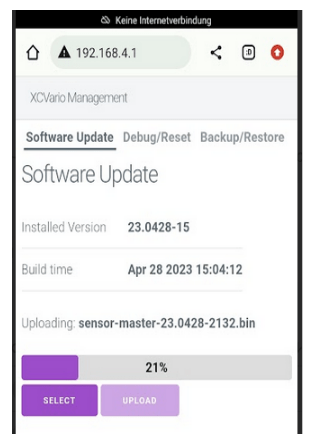

Device Management

An important feature is the XCVario management via the WiFi access point of the device. After activating the “ESP32 OTA” WiFi, e.g. by pressing a button when switching on immediately when the line with the software version appears, the adjacent management page can be called up via a WiFi-enabled device via the page https://192.168.4.1. Below that you can find the software update, under Debug/Reset a factory reset (see the separate chapter under “Setup”), a possible core file for debugging purposes, and under Backup/Restore a backup file of the configuration on the mobile phone , tablet or laptop and import it back to the device.

Software Update

Under the Software Update tab, the installed software version is displayed, as well as other details such as the exact time when the package was built. Using [SELECT], the file with the new software can be selected on the smartphone and then uploaded via [UPLOAD].

Debug/Reset

The operation is self-explanatory, after pressing the [FACTORY RESET] button, the execution must be confirmed in another dialog, the device is then reset to the factory settings. This means that all settings are lost unless there is a backup of the configuration (next point).

The [DOWNLOAD CORE DUMP] button provides a file that can be sent to the manufacturer for troubleshooting if the device shows malfunctions during operation, e.g. with new features that are still running in alpha mode, i.e. in test mode. The core file is only created if the system encounters a fatal error and the software restarts, and is deleted after uploading to the XCVario.

Backup/Restore

Here, too, the operation is self-explanatory, [BACKUP] writes all settings that deviate from the default, including the calibration of the compass, or a deviation table in a file which can be stored on the mobile phone, tablet or PC.

On the other hand, [RESTORE] loads the configuration from the file back into the device, which is very helpful, for example, when replacing a device or upgrading to a newer model or after a factory reset has been carried out. Basically, no factory reset is carried out during the restore, i.e. other settings that are not in the backup file are initially retained. If you only want to see these settings from the backup file, then a factory reset must be carried out beforehand. This means that, in addition to a clean restoration of an earlier status, there is also the possibility of a “merge” of the existing configuration with the status from the backup.

FLARM

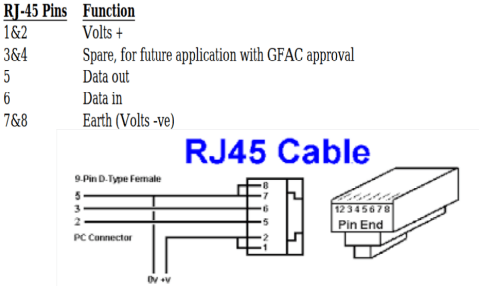

Every FLARM, whether classic, power or RedBox FLARM with RJ45 connection can be connected to the XCVario with standard cables. The cable available in the shop has the power option, with which the FLARM is also supplied via this cable. This saves additional wiring for the supply of the FLARM from the vehicle electrical system. Other FLARMs with RJ12 connector or Sub-D connector can also be connected with a modified cable.

If the FLARM is plugged in, the NMEA data from the GPS and barometric probe (if the FLARM is available) are sent to XCSoar with the FLARM cable as standard. With the bidirectional FLARM cable (see chapter Electrical connection /FLARM), tasks can also be written to an IGC-Flarm and settings of the FLARM can be made. See the description of XCSoar.

A flight download can also be carried out with the recorded flights in FLARM. To do this, the FLARM must be created as a separate device with the “FLARM” driver in XCSoar and activated for the download (Config/NMEA Connection/FLARM../Activate). During activation of the FLARM driver, other drivers such as OpenVario, which use the same Bluetooth connection, must be deactivated (Config/NMEA connection/OpenVario../Deactivate). The flight download can then be tapped in the FLARM device, a list of flights is first transmitted, from which the desired flight is then selected. The flight download via the serial interface can take a few minutes, depending on the length of the flight, since the data rate of the serial interface at the standard 19,200 baud only allows around 2 kilobytes per second. Higher data rates for faster downloading are possible, see the chapter on setting the baud rate of the serial RS232 interface. If XCSoar is connected via WiFi instead of Bluetooth, the FLARM can also be created as a separate device in XCSoar with the “FLARM” driver. It is then no longer necessary to create (or change) the device driver for the flight download or to switch to the Vario Setup menu. The flight download via the WiFi interface is possible with a WiFi device, which is connected via the Flarm port for the purpose. Other devices connected to the XCVario must be switched off during the download.

In the current software versions, there is also a simple FLARM screen to warn of an imminent collision with another aircraft, which graphically visualizes the distance, direction and height offset of the approach. Depending on the alarm level, an acoustic warning signal with an adjustable volume is also used to draw attention to the danger.

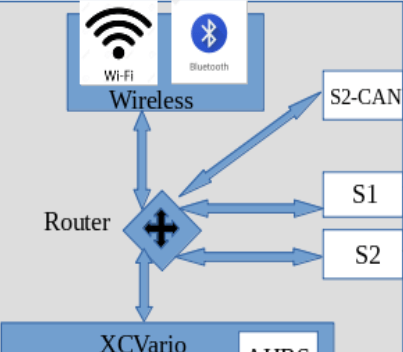

Configurations and Router

An important functionality of the XCVario is the integrated router function, which makes it possible to connect the data of the device and data from external devices between the various interfaces of the device. This results in a multitude of possibilities for using the XCVario and thus almost any extensions and possible uses are covered. An overview of this follows, further setups are conceivable and can be derived from the combinations shown.

It is generally recommended to switch off connections that are not required, as they unnecessarily occupy resources such as CPU and RAM, especially if there is no destination at the other end, the data accumulates, cannot be delivered and must be discarded. With a minimum setting for the routing, the full performance for the Vario operation of the device is available.

The routing of data that is sent to the XCVario from outside via any interface is always activated, i.e. the XCVario always reacts to FLARM and GPS data, commands, etc. without having to program a routing for this. For the XCVario data itself, i.e. the outward direction, the routing must be set accordingly for the interface. The XCVario data is also automatically routed to the CAN bus in the CAN mode master.

Configurations that require the CAN bus can therefore only be used from the current hardware series XCVario-22.

The configuration of the router is always bidirectional, i.e. both the forward direction and the reverse direction of the data streams are always connected.

Any of these ports can only ever be connected to one target bidirectionally. To setup the routing, see the “Routing” description in the setup chapter for the corresponding ports. The reverse direction is automatically configured, for example if we enable S1-RS232 as a target in the wireless interface routing settings, then at the S1-RS232 interface, the Wireless is enabled as well. The adjustment therefore only needs to be made at one end but is visible at both ends, means the routing setting appears in two places, and can be changed from either place, but it is the same setting.

XCVario, Wireless Navi and FLARM

The most common application in the single seater is the following. This setting also corresponds to the delivery status, a wireless navigation device and a Flarm with IGC standard connection therefore run via plug and play without having to make any further settings. In this configuration, the XCVario data must be routed to wireless (WL), and the data on S1 which come from FLARM are also of interest on wireless, so that a GPS fix on the navigation system and also the traffic of other aircraft can also be included FLARM can be displayed, so these two switches are set to “Enable”. The interface S2 and the CAN bus are not required for this. For more information, e.g. where to find the routing dialogs in the setup menu, please refer to the Setup chapter. Its mostly the default configuration, so for this nothing is to be altered in the router setup.

Minimum setup:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Disable | XCVario | Disable | XCVario | Disable |

| S1-RS232 | Enable | Wireless | Enable | Wireless | Disable | Wireless | Disable |

| S2-RS232 | Disable | S2-RS232 | Disable | S1-RS232 | Disable | S1-RS232 | Disable |

| CAN-bus | Disable | CAN-bus | Disable | CAN-bus | Disable | S2-RS232 | Disable |

XCVario, wired Navis and FLARM

For this with a wired Navi like Kobo, OpenVario, IPX, etc, the data from FLARM to S1 must be routed to S2 (S1: S2-RS232 = Enable, or S2: S1-RS232 = Enable). The settings are made in the routing of S1 and S2, all other ports are not required in principle, but it can make sense to leave the wireless settings on XCVario and S1 enabled, so that a second device can be connected wireless if necessary, e.g. in the event of a power shortage for the permanently installed device, or in the event of a failure. It is also possible to read out the IGC file wireless with a mobile phone after the flight. The device wired to S2 can remain in the cockpit, a memory card or a USB stick for data transfer is then not required.

Front device minimum setup:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Disable | XCVario | Enable | XCVario | Disable |

| S1-RS232 | Enable | Wireless | Disable | Wireless | Disable | Wireless | Disable |

| S2-RS232 | Disable | S2-RS232 | Enable | S1-RS232 | Enable | S1-RS232 | Disable |

| CAN-bus | Disable | CAN-bus | Disable | CAN-bus | Disable | S2-RS232 | Disable |

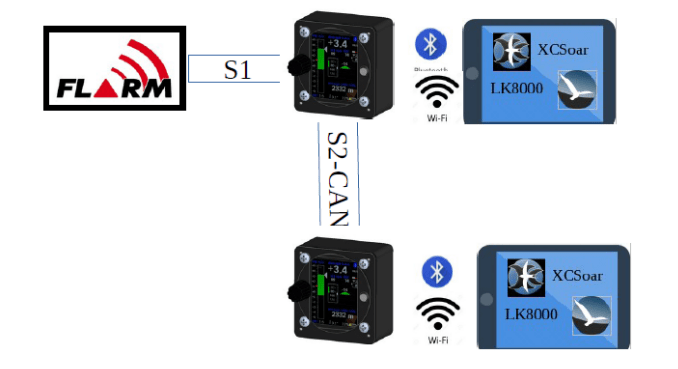

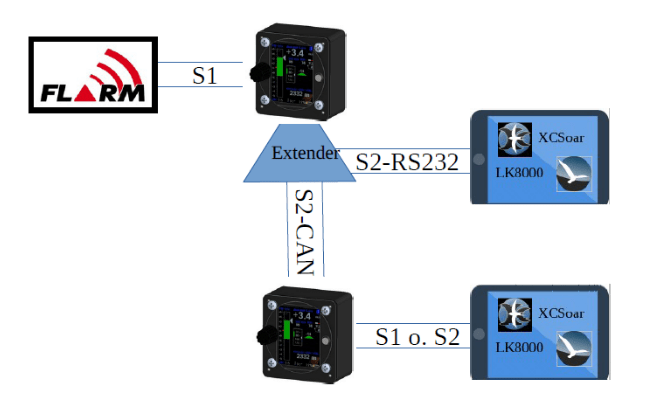

Two XCVario, two wireless Navis and FLARM

For two-seaters and two wireless navigation systems, the following configuration is available, in which the main device is connected to the FLARM at S1 in the front, and the second display for the rear seat is connected via the CAN bus Data from the XCVario itself is transmitted to the second display via the CAN bus. Only the front device has to be hosed. This is the simplest configuration for two-seaters and only requires a 1:1 patch cable between the S2 interfaces of the front and rear units.

Front device minimum setup:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Disable | XCVario | Disable | XCVario | Enable |

| S1-RS232 | Enable | Wireless | Disable | Wireless | Disable | Wireless | Disable |

| S2-RS232 | Disable | S2-RS232 | Disable | S1-RS232 | Disable | S1-RS232 | Enable |

| CAN-bus | Disable | S1-CAN | Enable | CAN-bus | Disable | S2-RS232 | Disable |

Secondary device:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Disable | XCVario | Disable | XCVario | Enable |

| S1-RS232 | Disable | Wireless | Disable | Wireless | Disable | Wireless | Enable |

| S2-RS232 | Disable | S2-RS232 | Disable | S1-RS232 | Disable | S1-RS232 | Disable |

| CAN-bus | Enable | S1-CAN | Disable | CAN-bus | Disable | S2-RS232 | Disable |

Two XCVario, two wired Navis and FLARM

For two-seaters with two wired navigation systems, the picture is similar to the last configuration, the front navigation system can be connected to S2, the rear navigation system to S1 or S2. With a connection via S1 on the second device, the IGC-compatible Flarm port of the standard cable set is ideal if the device also has serial ports according to the IGC standard, or a connection to S2 with a 1:1 patch cable. In this case, the same routing settings “CAN” and “XCVario” as shown for S1 are to be made on the second device instead on S2. When connecting to S2 in the rear cockpit, use one of the extenders as shown in the front unit.

Front device minimum setup:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Disable | XCVario | Enable | XCVario | Enable |

| S1-RS232 | Enable | Wireless | Enable | Wireless | Disable | Wireless | Disable |

| S2-RS232 | Disable | S2-RS232 | Enable | S1-RS232 | Enable | S1-RS232 | Enable |

| CAN-bus | Disable | S1-CAN | Enable | CAN-bus | Disable | S2-RS232 | Disable |

Secondary device:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Enable | XCVario | Disable | XCVario | Enable |

| S1-RS232 | Enable | Wireless | Enable | Wireless | Disable | Wireless | Disable |

| S2-RS232 | Disable | S2-RS232 | Disable | S1-RS232 | Disable | S1-RS232 | Enable |

| CAN-bus | Disable | S1-CAN | Enable | CAN-bus | Disable | S2-RS232 | Disable |

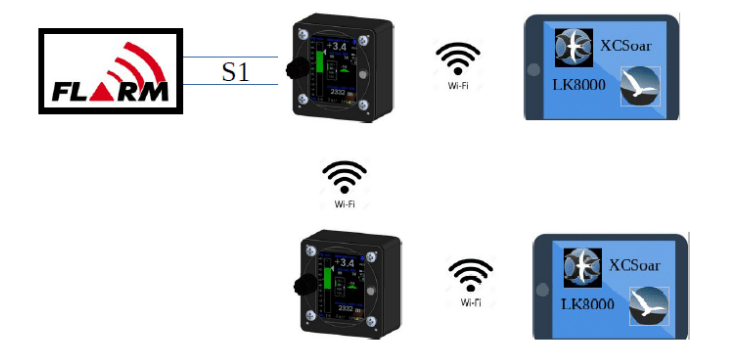

Two XCVario wireless, two wireless Navis and FLARM

This configuration does not require any cabling between the front and rear devices. Both the navigation system and the two XCVarios can be coupled via WiFi. In Options / Wireless, the front device must be set as the wireless master and the rear device as the wireless client. Since Bluetooth and WLAN are only possible as alternatives, only the WLAN connection is possible, further details on this can be found in the Settings / Wireless chapter. The default for the routing can be used here. Only the setting for S1 on the first device is relevant, as well as the WL routing on both devices.

Front device minimum setup:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Disable | XCVario | Disable | XCVario | Disable |

| S1-RS232 | Enable | Wireless | Enable | Wireless | Disable | Wireless | Disable |

| S2-RS232 | Disable | S2-RS232 | Disable | S1-RS232 | Disable | S1-RS232 | Disable |

| CAN-bus | Disable | S1-CAN | Disable | CAN-bus | Disable | S2-RS232 | Disable |

Secondary device:

| Wireless Routing | S1-Routing | S2-Routing | CAN Routing | ||||

| Port | Setting | Port | Setting | Port | Setting | Port | Setting |

| XCVario | Enable | XCVario | Disable | XCVario | Disable | XCVario | Disable |

| S1-RS232 | Disable | Wireless | Disable | Wireless | Disable | Wireless | Disable |

| S2-RS232 | Disable | S2-RS232 | Disable | S1-RS232 | Disable | S1-RS232 | Disable |

| CAN-bus | Disable | S1-CAN | Disable | CAN-bus | Disable | S2-RS232 | Disable |

Basic Setup

The following Chapters is dedicated to the setup elements as there are in the device in English language. Because of that those elements are only translated from English in the table of contents here, not in the headlines or select lists in the following chapters about the setup.

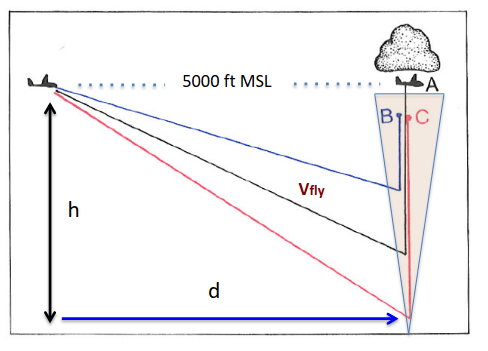

MC

0.5 m/s

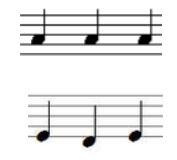

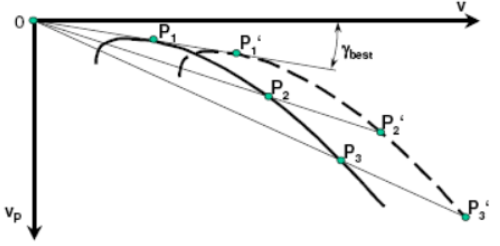

Here the MacCready value (MC) can be set from 0 in 0.1 m/s steps to 9.9 m/s. After confirming with a short press, the Vario is immediately back in normal operation. The MC value can be described as an Optimum Airspeed Selector, according to the mathematics developed by Paul MacCready. This crosscountry “airspeed selector value” is indicates the optimum speed at which a sailplane should be flown between thermals. In the picture on the right, case A shows the optimum setting, B a too low and C a to high MC setting.

Bugs

0 %

Degradation of the flight polar by insects can be adjusted via the parameter Bugs (insects). Here, the coefficients of the polar parabola a0, a1, and a2 are worsened according to the percentage. The flight polar can be deteriorated by this parameter in percentage terms. Whereby the absolute, the linear, as well as the quadratic coefficient are degraded, which equates to a greater degradation at higher speeds. The procedure is identical to the polar degradation procedure used in XCSoar, and is the common procedure for accounting for insects in glider polars.

Maximum degradation is 50% in accordance with XCSoar. Values like 10-20% are realistic for modern profiles. However, older profiles that are more sensitive to rain and mosquitoes, e.g with a LS3, Kestrel or Nimbus 2, can largely exhaust the value range with very heavy soiling.

Ballast

80 liters

39.00 kg/m2

The water ballast can be set in the ballast dialog. In addition, the wing loading resulting from the additional ballast is displayed. 1 liter of water normally corresponds to 1 kg of ballast.

Example: A glider with a wing area of 10 m2 has a setup weight of 260 kg, the pilot weighs 80 kg, 100 liters of water (100 kg) are in the tank. The take-off weight is 440kg, corresponding to the wing loading 440kg/10m2 = 44 kg/m2.

Crew Weight

80 kg

With the “Crew Weight” or pilot and passenger weight, the weight of the pilot, if necessary also of the passenger in twoseaters including parachute and luggage should be recorded. The default setting is 80 kg. A correct weight contributes to the correct determination of the wing loading and thus to a better agreement of the polars with practice, and provides more accurate values for the speed to fly and the net vario, as well as the other weights.

QNH

1013.25 hPa

Dialog for setting the QNH value. On the ground, set the value so that the altimeter display also shows the airfield elevation, or to the QNH value of the nearest ATC.

Airfield Elevation

-1 m

If the value for the airfield elevation is recorded here, the QNH is automatically adjusted to the given airfield elevation after switching on. In the QNH dialogue, the QNH then only has to be confirmed. If you land on another airfield with a different altitude, use the local QNH when switching on, or adjust the airfield elevation to the new altitude if you want to use the auto setup for the QNH. The default setting here is -1 meter, so the feature is switched off and the last recorded QNH is used and must be adjusted conventionally.

Vario and Speed 2 Fly

The settings for the vario display and the speed to fly can be adjusted in the Vario dialog.

Range

5 m/s

The scale of the variometer is set with the range. A range from 1 m/s to 30 m/s can be selected for the min/max values. Default is 5 m/s.

Log-Scale

[DISABLE] [ENABLE]

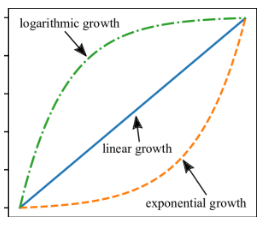

With the help of this option, the pointer display of the variometer can be shown with a logarithmic scale. The area around the zero point is stretched, and the areas towards the end of the scale are gathered. The mode has the advantage of being able to display a significantly larger measuring range without losing accuracy around the zero point. Another decisive advantage: This means that relative changes can be better evaluated, which means an improvement in climb of 20% at 1 m/s, i.e. an increase of 0.2 m/s, corresponds to the same way on the scale as relative improvement by 20% at 5 m/s, equivalent to 1 m/s.

Mode

[Brutto] [Netto] [Cruise Netto]

With this setting you can choose whether the variometer works as a gross vario, i.e. without taking account of the polar sink rate, or as a netto vario with the polar sink rate being calculated out.

The “Cruise-Netto” setting selects the net setting exactly when the vario is in speed-to-fly mode, otherwise the vario works as a gross variometer, which makes sense when circling, because for the MacCready setting the gross rate is relevant.

Of course, the audio signal also follows the set mode. In the gross setting, the acoustics only report climbing when the surrounding air mass rises faster than the polar sink rate, i.e. the aircraft is actually climbing. In the netto setting, the audio signal is coupled to the net climb, so as soon as the surrounding air mass rises, the acoustics also indicate climb. This makes sense, for example, to better recognize small changes in the surrounding air mass when flying fast ahead, since the sometimes higher sink rate in net mode is otherwise compensated.

Netto Mode

[Normal] [Relative]

With this setting, the net mode can be further refined. In the [Normal] setting, only the polar descent is taken into account for the current speed, so the variometer display corresponds exactly to the rise or fall of the surrounding air mass. In the display, this setting for the normal net is signaled with “net” in the top status line.

For example, if you circled the net display at 2 m/s, you would have a slightly less effective (gross) climb than the pure net value due to the inherent sink rate when turning, e.g. an LS-4 with an inherent sink rate of 0.6 m/s when turning only 1.4 m/s.

In order to take this into account, the net mode setting [Relative], often also called “Super Netto” (default), also takes into account the inherent sink rate when circling, specifically the inherent sink rate that occurs when circling with a 45° bank angle at the optimal speed would be. So it shows the value that you would have in terms of gross rises if you circled at the point. The display of the vario would be 1.4 m/s in this case, and further reduces the workload in the cockpit, since one no longer has to calculate the value of the expected climb in order to assess whether circling is worth as displayed directly in Super-Netto mode. This setting is signaled with “s-net” in the status line.

Polar Sink

[DISABLE] [ENABLE]

By selecting [ENABLE] (default setting), the polar sink rate is displayed in relation to the speed in the gross mode of the variometer. With [DISABLE] the display can be switched off, the polar sink rate is then no longer displayed. The polar sink rate is shown in the airliner style as a blue bar, in the retro style as a blue arc starting from the zero point and pointing downwards.

Needle Color

[White] [Orange] [Red]

Option for the color of the vario pointer. In the default setting, the vario pointer is white [Orange], but can also be displayed in orange or red (Red).

Center Aid

[Disable] [Enable]

With the option for the center aid, you can choose to show a center aid in the retro display. The default is [Disable], with [Enable] the centering aid is displayed. The feature is still new and has yet to be tested in flight. In the lower half of the scale, it shows green dots on a circular arc, which increase with the strength of the updraft relative to the flight direction (heading), and is intended to support the pilot in shifting the circle accordingly for better climbing. If there is no magnetic sensor, the course over ground from a possibly connected Flarm or GPS is used as a reference.

Vario Damping

3 sec

Damping controls the time constant for smoothing the variometer display. Normal thermals are inherently turbulent, which means that an undamped vario display provides the pilot with little information that can be evaluated. Time constants of a few seconds are common. Too much damping delays the display with simple low-pass filters. The optimized Kalman filtering, which takes physical conditions into account and thinks ahead, reacts quickly without appearing nervous. The default is 3 seconds. Values up to 6 seconds can be useful for an even smoother display.

Averager

20 sec

This damping controls the time constant for smoothing the digital average variometer display, top center of the display. The default is 20 seconds, so the digital display shows the average climb over the last 20 seconds. This is a fairly common value in many variometer systems, and gives the pilot an indication of the current strength of the thermal. Insufficient attenuation leads to poor legibility and offers hardly any useful information due to the nervousness of the display. The value can theoretically be increased to 60 seconds.

Mean Climb

Minimum climb

0.5 m/s

The Mean Climb min(imum) setting. For the calculation of the average climb, small climb values, which are present, for example, in straight flight at high speed, can be hidden. A modern recommendation (http://aboutgliding.com/005-a-small-error-in-maccready-theory/) In the following, only the core climb when circling should be used for the MC value, and not the climb values in straight flight or when centering. This value defines the minimum climb from which a climb value is still taken into account in the calculation of the mean climb. The default is 0.5 m/s.

Duration

45 min

According to the recommendations, the climb values of the last 3 thermals should also be taken into account as the average climb for the MC value. From the analysis of many flights you can see that a new updraft area is approached about every 15 minutes. This is taken into account with a default setting of 45 minutes for the “Mean Climb dur(ation)”, i.e. only values from the last 45 minutes are taken into account. The value can be changed in minute increments.

Cycle

60 sec

This setting determines how often the mean climb is calculated. The “Mean Climb cycl(e)” defines the period in which this occurs. The default is 60 seconds, the value can be tuned between 60 and 300 seconds. A circle with a 45% bank angle usually lasts about 20 seconds with a glider, 60 seconds corresponds to about 3 circles. This is a good value to gather enough data for the new Mean Climb indicator and to be able to clearly show the trend (shape/color of the diamond) accordingly. Shorter times lead to small values and tend to weaken the trend signaling.

Major Change

0.50 m/s

“Major Change” is the value for the change in average climb, which is graphically represented by a symbol change. If the value is exceeded, the shape of the route changes and the diamond lengthens up or down. The default is 0.5 m/s.

S2F Settings

Damping

5.00 sec

The S2F (Speed to Fly) can also be dampened within certain limits, the default is 5 seconds. Greater dampening smoothes but also delays the S2F display, so that after leaving the thermal, the speed to fly does not immediately increase in line with the sink. The value can be set in 0.1 second steps up to a maximum of 10 seconds. In modern aircraft with high wing loading and high cruise speeds of over 150 km/h, it makes little sense to react to short thermals. This would even be counterproductive, since unfavorably high load factors then occur due to inertia, which reduces the performance, which speaks for a damping of the S2F. When lined up, it makes sense to react with constant climbing or in a blue hole with constant falling, which is also very possible with a certain amount of damping. The default value of 5 seconds can be tuned by the user.

Blockspeed

[DISABLE] [ENABLE]

By setting the block speed [Enable], the rising or falling of the surrounding air mass (according to the value of the net vario) is suppressed. Only the load and the MacCready value are then included in the calculation of the optimal speed. The speed that the speed command then displays remains constant in the thermal, which follows the theory that pulling up with typical thermals lasting a few seconds does not necessarily make sense due to the inertia of the aircraft. This was proven years ago by numerical simulation at the Technical University of Munich, and it was shown that the MacCready speed for the upwind case only makes sense from a certain thermal duration of approx. 20-30 seconds (half the period of the phygoid or natural frequency, also called pump frequency) , or if you really want to crank. Some well-known pilots fly this style and achieve good average speeds with it.

S2F Mode

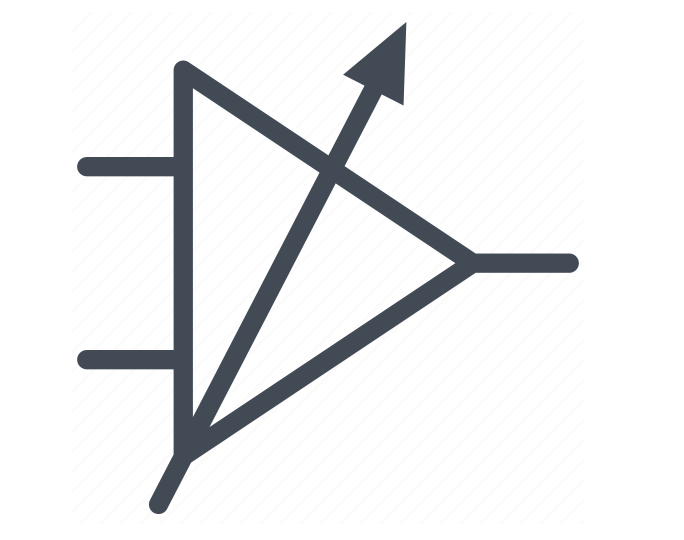

[Vario fix] [Cruise fix] [Switch] [AutoSpeed] [External] [Flap] [AHRS-Gyro]

The S2F ‘Mode’ specifies the procedure used to switch between circling and speed to fly. There are four options. The mode can either be fixed to Vario [Vario] or Speed to Set [Cruise]. The instrument then does not change modes, and remains fixed in either circling or speed command mode. In practice, when flying cross-country, these two settings make little sense, at most the vario mode can make sense if you don’t want to fly according to the speed to fly and always want to see a conventional vario display.

The speed command is always visible, so a speed command is also displayed in “Vario” mode, but this is the optimum circling speed with the current load for the minimum sink in a turn of approx. 45°. The resulting 1.4-fold load factor (+40%) is taken into account with a speed increase of ~20%.

There is also the option of using an external switch, e.g. a stick switch or tactile switch (more modern) on the I panel, better on the stick to change between vario and speed to fly. The switch must of course be operated, which increases the workload in the cockpit, but offers maximum flexibility. If you want to avoid this and if you want the switchover to take place automatically from a certain speed, select [AutoSpeed] (default setting). The speed to switch over can be set in the following menu item: “S2F AutoSpeed”.

In [External] mode, the speed to fly setting is taken over by a second variometer, either coupled via Bluetooth or via the CAN bus from series 2022. The second device can be either the rear or the front variometer, depending on where you put the switches or want to wire the button. Select Switch (or Autospeed) on the device that should react to the switches. On the second device that you want to synchronize, the “External” mode.

Warning: The “Cruise from Master” mode has been replaced by this setting, so synchronization can now also be done from the client.

The [Flap] mode allows you to switch the speed command mode to circling mode via the optional flap sensor. The changeover takes place exactly when the flap exceeds the value of “S2F Flap Pos”.

The [AHRS-Gyro] mode can be used on all devices except the 2020 series, and it automatically switches to circling flight mode if the rotation speed in degrees per second is greater than the “S2F AHRS Deg”. The measured rotational speed is the value averaged over 20 seconds and provided with a hysteresis of 20%, it is only switched back when the value is 20% lower than the set value.

S2F Switch

[Switch] [Push Button] [Switch Inverted] [Disable]

The type of speed command switch can be set, a switch [switch] is preset, but a button [push button] can also be selected, which changes the setting each time the button is pressed. This can make sense, for example, when using a Stefly stick input device equipped with buttons. The [Switch Inverted] option stands for a switch with the reverse function, i.e. the speed command mode is then selected when the switch is open instead of when the switch is closed. The switch can change mode at any time, even if set to [AutoSpeed], [Flap], or [AHRS-Gyro], unless set to [Disable].

S2F AutoSpeed

100 km/h

This is the speed in AutoSpeed mode at which the variometer changes from circling to speed command or cruise mode. The default is 100 km/h. With higher wing loading and modern gliders, the value can be set correspondingly higher.

S2F Flap Pos

1

This setting defines the flap position at which the S2F mode should be switched in the “S2F mode” [Flap]. By default, the flap position is set to +1.

S2F AHRS Deg

12 °

This sets the threshold for the rate of rotation in degrees per second at which the device switches to S2F mode in [AHRS-Gyro] mode. Small values switch to thermal mode early on when circling, while larger values switch with a delay due to averaging over approx. 20 seconds. A typical circle with a duration of 30 seconds has a rotation rate of 360/30 = 12° degrees per second, which is the default.

Hysteresis

5 Seconds

With the hysteresis, the automatic, controlled by the airspeed switching (AutoSpeed mode) to target flight can be calmed down. Without hysteresis, the mode may switch back and forth frequently at an airspeed around the set AutoSpeed. A hysteresis of 5 Seconds (default setting) switches to speed to fly mode when the speed is bejond the threshold for the given hysteresis time.

Arrow Color

[White/White] [Blue/Blue] [Green/Red]

The color of the speed to fly arrow can be set individually under “Arrow Color”. The first color is for the up arrow, the second color is for the down arrow. The last arrow is displayed in a different color if the range is exceeded. 3 arrows are displayed with the levels 10, 20 and 30 km/h. If the deviation is more than 30 km/h, the case of exceeding is given.

Electronic Compensation

With electronic compensation, you can optionally achieve total energy compensation for the Vario without a TE nozzle. The feature is still in the optimization phase, but already works in principle.

Good electronic compensation requires well-placed and functional static and dynamic pressure taps. Many factors play a role here, starting with the mass of the air trapped in the pressure lines, pressure changes along the fuselage and in the wing area, accelerations and more. It is therefore advised to generally use TE nozzle compensation, which works better in most cases. The parameters that play a role in good compensation can be found in the .pdf scan of the following paper, which Mr. Brözel from ILEC compiled at that time: https://xcvario.de/wp-content/uploads/2021/11/GliderInducedErrorsinTotalEnergyVariometry.pdf

eCompesation

[TEK Probe]

[EPOT]

[PRESSURE]

The default here is [TEK Probe] means no electronic compensation and today is the recommended way once your glider has a TEK probe. The settings [EPOT] or [PRESSURE] enables the electronic compensation. In this modes the TEK nozzle pressure is no longer relevant and in principle does not need to be connected. If those setting is selected, only the pressure connected to ST, the static pressure, is used. This can make sense if no TE nozzle is available. Two different methods are available by today.

The first method [EPOT] calculates from true airspeed the potential energy expressed in meters and joins this with the barometric altimeter to create the vario signal. This method is more accurate in terms of mathematics, hence is more sensitive to dynamic effects what can be an issue in high performance gliders.

The second method [PRESSURE] is new and experimental is based in pressure readings from ST and PI port, and directly joins this pressures in the same way as the TEK probe does. The second method might bring better results in dynamic situations, so maybe more useful for high performance machines, flight tests shall bring a clearer picture here, you may try it yourself and give us feedback.

Adjustment

0.00 %

Both methods for electronic compensation can be tuned by this parameter. The compensation can be adjusted positively or negatively in 0.1% steps up to +/-50% using this percentage factor. This factor decreases or increases the theoretical kinetic energy, which is converted into height during hoisting (V2/2g). In the case of under-compensation (vario shows increase when pulled up), the value should be increased until the display is correct. The same applies to overcompensation with negative values. It is also advisable to increase the preset damping of the Vario from 3 seconds to at least 5-6 seconds in order to minimize transient effects (short-term deviations). The rapidly converging Kalman filter then still reacts sufficiently quickly to changes.

Similar effect for adjustment is there when the pressure method is used, then this factor applies to the total (PI) pressure that is being subtracted from the static pressure.

Audio

Audio

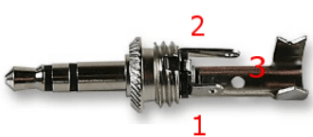

The sound generator is an important part of an electronic variometer to improve safety in the cockpit, as it allows you to look out in order to pay attention to other aircraft. The tone changes in pitch and interval between the pauses (or a second tone) with the vario or speed command indicator, and is emitted through the internal speaker on the rear of the housing or a plugged in external speaker.

Volume Options

Current Volume

4%

Display of the current volume setting as set by rotary.

Current->Default

[Cancel] [Set]

This setting takes over the current volume as is set by rotary at that time for the default volume on next start.

Default Volume

10 %

In this setting, the volume that is used after switching on the device is configured. The default is 10% volume.

Max Volume

100 %

In this setting, the maximum possible volume of the device is configured. The default is 100% volume. If the loudspeaker used, e.g. with an external loudspeaker, shows distortion at the maximum volume, or if a limit is desirable, the value can be reduced here. For example, a setting of 50% reduces the volume by about 6 dB.

Equalizer

[Disable] [Speaker 8 Ohms] [Speaker 4 Ohms] [Speaker External]

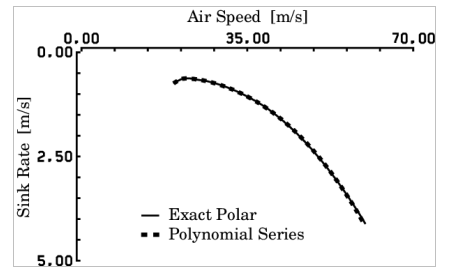

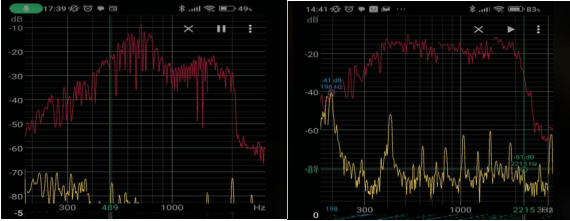

The audio equalizer ensures a uniform frequency response of the audio output, see image on the right (red curve). In the picture on the left you can see the frequency response of the speaker without the equalizer switched on according to [Disable]. The equalizer increases or decreases volume as a function of frequency, as shown here, to attenuate the speaker’s resonant frequencies at 800 and 1600 Hz, as well as boost other areas to achieve an overall balanced frequency response over a wide frequency range (right image). The most commonly installed 8 ohm speaker is selected by default, some devices were delivered with a 4 ohm speaker, which differs slightly in the frequency response. If the setting of 8 ohms does not fit, or if an external loudspeaker is used, then switch to [Speaker 4 Ohms] or [Speaker External]. The correct setting has been found when approximately the same volume can be heard for all frequencies. The series 2023 varios have a speaker with a flat frequency response and do not need equalizer so the default in recent SW builds is [Disable].

Frequency Response

30 %

Since the sensitivity of human hearing increases continuously by approx. 6 decibels per octave in the range from ~30 Hz to 4000 Hz, higher tones sound significantly louder than lower ones, or low frequencies can hardly be heard at a comfortable volume from high tones . This setting takes this into account and reduces the volume per octave by the specified factor. A factor of 50% (amplitude) would correspond to an attenuation of exactly these 6 decibels, since the dynamics of the system are limited, 30% is preset, which represents a very good compromise. If higher frequencies are perceived less well, which is usually normal in the second half of a pilot’s life, this value can be reduced to 0%.

STF Volume

[Disable] [Enable]

With this feature, which adjusts the volume separately in Vario mode and in speed-to-fly mode, the volume can be adjusted to the different acoustics in the cockpit when circling and in fast flight. In older gliders flying at high speed, a higher volume is often necessary so that the sound can still be heard. The feature takes some getting used to and is switched off by default. With [Enable] it is activated.

Mute Audio

Options to mute audio in different situation like in sink, in setup, generally and disable amplifier in order to save a bit power.

In Sink

[Stay On] [Mute]

Decide if audio shall be mute or not when you are in a sink.

In Setup

[Stay On] [Mute]

Decide if audio shall be mute or not when you enter setup menu.

Generally

[Audio On] [Alarms On] [Audio Off]

Decide which features of audio that shall be on, vario and speed to fly audio, or only alarm or no audio.

Amplifier

[Stay On] [Shutdown]

Decide if the digital audio amplifier shall be just muted or shutdown during silence. Note that the amplifier needs ~200 mS for starting up, so there is a small delay when shutdown mode is selected.

Turning off the amplifier saves power (approx. 3-4 mA at 12V), and suppresses residual noise from the system, the vario does not make any noise.

Cruise Audio

[Speed2Fly] [Vario]

This setting is used to select which sound signal is generated in speed command mode. In the [Speed2Fly] speed command mode, a tone is generated which signals the deviation from the speed command. If the airspeed is too high, a progressively higher, optionally interrupted tone is generated, if the airspeed is too low, a lower tone. In the [Vario] setting, the audio signal remains in the vario setting and can, for example, signal net climbing if the vario is set in “Net Mode” or “Cruise Net Mode”. For more information, see the “Vario Mode” setup.

Tone Styles

CenterFreq

500 Hz

Specifies the center frequency of the tone generator (sine) and can be modified in 10 Hz steps between 200 Hz and 2000 Hz. The default is 500 Hz.

Octaves

2.00 fold

This determines how many octaves the tone change extends between the lowest and the center frequency (Center Frequency) and the highest or lowest tone. The value can be changed in 0.1 steps between 1.5 times and 4.1 times. The default is 2x, which means that with a center frequency of 500Hz, the highest tone is 1000Hz and the lowest tone is 250Hz. Too high a value produces tones outside the optimal spectrum for the loudspeaker and human hearing.

Dual Tone

[Disable] [Enable]

This setting is used to select whether a simple tone [single tone] with short interruptions is desired (di di di di) or whether the vario works in two-tone mode [dual tone] (di da di da). The default mode is with single tone and interruptions.

Dual Tone Pitch

12%.

This setting is only relevant in two-tone mode. It indicates the pitch, i.e. the pitch change of the second tone. The second tone is shifted up in pitch by this percentage. The default is 12%.

Chopping

[Disabled] [Vario Only] [S2F Only] [Vario and S2F]

With audio in vario or speed to fly (S2F) mode, the sound can be selected at values above zero with short interruptions (100 mS), the frequency of which increases with the displayed vario or S2F value. This interruption (chopping) can be switched off [Disabled], or apply only to Vario [Vario only] or the speed command [S2F only]. A fourth option is a break for both modes [Vario and S2F], which is the default. The maximum interruption frequency when the scale is struck is exactly 10 Hz, the minimum frequency is 1 Hz. In between, the frequency increases linearly with the display value.

Chopping Style

[Soft] [Hard]

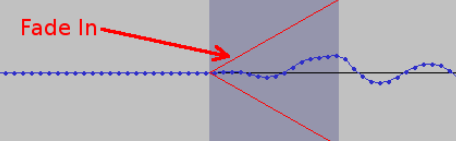

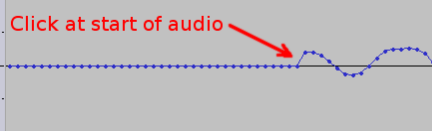

If the sound is interrupted by chopping, a certain “click” sound is heard when switching on and off, this is due to the spontaneous square-wave power change which generates harmonics. In order to minimize this effect, the [Soft] setting slowly ramps up the power within a few milliseconds (fade-in) and slowly ramps it down again when switching off (fade-out). The setting is a matter of taste, the default is the soft mode, which is mostly perceived as more pleasant.

Variable Tone

[Disable] [Enable]

Between chops enable or disable frequency changes. The sound may appear a bit ghostly when this feature is enable, but the feedback is more direct than in disabled mode.

Range

[Fixed 5 m/s] [Fixed 10 m/s] [Variable (=N m/s)]

This determines whether the tone generator follows a fixed range setting [Fix 5 m/s] or [Fix 10 m/s] or follows the current variometer range setting [Variable (=N m/s)]. The range determines from which value the tone generator outputs the highest or lowest frequency and interval sequence. It can make sense to assign the range dynamically in the case of a weak climb. With a dynamic setting and a range of 2 m/s of the vario, 2 m/s then sound the same as 5 m/s with a fixed setting. The default is [Fixed m/s].

Deadbands

[Lower Vario] : – 0.30 m/s [Upper Vario]: 0.30 m/s [Lower S2F]: – 10km/h [Upper S2F]: + 10km/h

The deadband is the area where the vario does not emit any sound (muted). There is the [Lower ..] setting for the negative value and the [Upper ..] setting for positive values. The default is +-0.3 m/s for the vario deadband. The deadband helps to hide small climb values and to ensure silence on the ground without having to turn down the volume. The target travel (S2F) also has a deadband, preset are -+10km/h only when the target travel difference from this value is exceeded is the muting canceled.

Audio Exponent

1.00

With this option, the relationship between the pitch and the Vario (or S2F) value can be optimally adapted to the circumstances. The default is 1.0, i.e. a linear relationship. Values less than 1, e.g. 0.5 produce a magnifying glass effect around the zero point. This is either a setting for flat land, when mainly small climb values are to be expected. Small vario values then lead to larger changes in the sound, the pilot is already alert with smaller climb values. Values greater than 1, e.g. 1.5 dampen the audio signal for small climb values. This, on the other hand, draws attention to high climb rates. This can make sense in the mountains if very good climb rates are to be expected.

Glider Details

In the loading/polar dialog, the right polar for the aircraft type is selected, masses can be adjusted and the polar that is set can be tuned manually.

Glider Type

[User Polar] [Antares 20E] [ASK 21] :

With this the polar for the corresponding type of aircraft can be set.

There is also a polar [User-Polar], e.g. for an aircraft type that is not contained in the library. the

[User Polar] is selected by default and corresponds to the values for an LS4a. There is an extensive and constantly growing library.

The current list of supported polars in the library can be found here: https://github.com/iltis42/XCVario/blob/master/main/Polars.cpp

Note: When updating from older software versions before mid 2021, the set polar must be checked after the update, the adoption of the setting may not be correct. With an upgrade from newer software versions from June 6, 2021, the problem is solved and the check is no longer necessary.

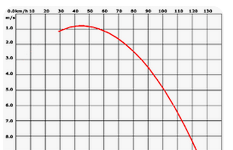

Polar Points

[Wingload] 34.4 kg/m2 [Speed 1] 80 km/h [Sink 1] – 0.66 m/s [Speed 2] 125 km/h [Sink 2] – 0.97 m/s [Speed 3] 175 km/h [Sink 3] – 2.24 m/s

Under PolarAdjust, the reference wing loading and the sink values for the individual speeds can be modified. The reference wing loading is the value at which the polar was flown and is usually given with the polar. If the current wing loading is higher even without ballast, then this must be set under “Fixed Ballast” see below. Normally, the reference wing loading should not be changed and must agree with the information from the polar. For this wing loading, the corresponding sink values [Sink 1,2,3] are to be set at three points according to the polars from the flight manual at the corresponding speeds [Speed 1,2,3]. The respective decrease is recorded as a negative value. Ideally, you should take the first speed around the lowest sink rate, then an average speed and a reasonable highest speed which is relevant for the cruise mode.

Modifications to the selected polars are reset by selecting a different aircraft type. Normally, only the aircraft type has to be set, an adjustment of the above parameters is not normally necessary, further aircraft types are promptly integrated into the library by XCVario on request, and are immediately available after a SW update.

Max Ballast

160.00 liters

The maximum possible water ballast can be modified here. This parameter is usually given by the aircraft type and comes from the polar library according to the manufacturer’s information, but can vary due to modifications such as adding winglets or installing other water bags, and can be modified here accordingly.

Wing Area

10.5 m²

Here the wing area can be modified. These parameters are actually given by the aircraft type, but can vary due to modifications such as attachable wings or winglets, and can be modified here accordingly.

Empty Weight

265 kg

With “Empty Weight” or empty mass, the empty weight or empty mass can be set more precisely. Gliders tend to get heavier over time, not only because of the installation of instruments, the addition of winglets or repainting, but also the CFK or GFK itself draws water over time and becomes heavier as a result. In order to take this into account, the empty weight can be set to a higher value than that which was used as the basis for determining the gliding polars in the comparison flight. As a default, when selecting the polar, the empty mass is entered from the flight weight minus the pilot’s weight. A higher empty mass thus improves gliding at higher speeds and, like normal water ballast, contributes to increasing the wing loading.

Options

Student Mode

[Disable] [Enable]

With the “Student Mode”, if “Enabled”, only the settings necessary for the flight are shown in the setup menu, such as MacCready, Audio Volume, QNH Setup, Ballast, Bugs and Airfield Elevation. All other setting options are then hidden. The mode can be ended again by turning in the “Expert Password” 271 on the rotary switch and restarting. Then all setup options are displayed again.

The mode can make sense for clubs to prevent unintentional twisting of an important parameter in a training aircraft. By default, this mode is turned off.

Airspeed Mode

[IAS] [TAS] [CAS] [Slip Angle]

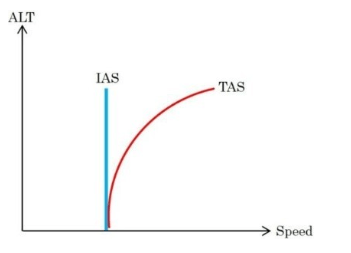

In addition to IAS (Indicated AirSpeed), i.e. the displayed speed, which deviates slightly from the true value in terms of height, the TAS (True AirSpeed) and CAS (Calibrated Airspeed) is also available as an alternative.

The TAS increases at higher altitudes and corresponds to the true speed and is comparable with the ground speed of the GPS without wind, which shows a higher value at higher altitudes. The “Slip Angle” setting shows instead of the speed an estimate of the slip angle in degrees determined from the acceleration values, roughly corresponding to the thread, which plays a role in the wind calculation in straight flight.

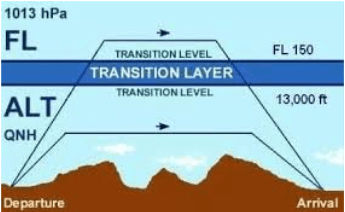

Auto Transition

[Disable] [Enable]

With this setting, the altimeter can be automatically switched to QNH standard 1013.25 hPa from the “Transition Altitude”.

Transition Altitude

50.00 FL

With this setting, the country-specific “Transition Altitude” can be set as Flight Level (FL). This is only relevant if the automatic transition from the previous point is switched on (Enable). Below the transition altitude, the QNH setting applies to the altimeter, above that it switches to QNE according to the standard 1013.25 hPa.

Units

Units

For international use, the units for the variometer, the airspeed the altimeter, temperature, QNH and distance can be set as desired. The setting options are as below, the defaults are printed in bold.

Altimeter

[Meter (m)] [Feet (ft)] [Flightlevel (FL)]

Airspeed

[Kilometers/hour (km/h)] [Miles/hour (mph)] [Knots (kt)]

Vario

[Meter/sec (m/s)] [Feet/min x 100 (fpm)] [Knots (kt)]

Temperature

[Celcius] [Fahrenheit] [Kelvin]

QNH

[Hektopascal] [InchMercury]

Distance

[Meter (m)] [Feet (ft)]

Flap (WK) Indicator

Flap (WK) Indicator

The “Flap Indicator” shows the pilot the optimal setting of the flap depending on the wing loading and the speed in straight flight. The default setting for the flap indicator is switched off and can be switched on with [Enable]. The speeds from the flight manual for the wing loading of the polars entered should be recorded.

Flap Indicator

[Disable] [Enable]

Here you can [Enable] or [Disable] the feature of the flap display. By default, the display is off. The optimal latching of the flap is indicated with the green triangle as shown above. The green triangle moves vertically according to the set speed ranges for the flap positions.

Max postitive Flap

2

Two positive flap positions are preset. The number of positive flap positions can be selected here. Between 0 and 3 positive flap positions are available. According to this setting, these flap positions are visualized, as well as menu items for recording the speed ranges, and the values for calibration are recorded if the sensor is present.

Max negative Flap

-2

As above for the number of negative flap positions.

Takeoff Flap

1

Here you can set which flap position should be displayed when there is no dynamic pressure on the ground. Normally this is the position required for take off and is usually found in the flight manual. Depending on the load and the wind situation, the setting may require correction. In case of doubt, the flap position specified in the flight manual for the respective situation always applies.

Flap Speeds Setup

The optimal speed ranges are recorded under the following entries, shown here for three positive and three negative flap positions. Only those values are used which are given by the maximum positive and negative setting.

Speed +3 to +2 70.00 km/h Speed +2 to +1 78.00 km/h Speed +1 to 0 88.00 km/h Speed 0 to -1 105.00 km/h Speed -1 to -2 165 km/h Speed -2 to -3 195 km/h

Flap Position Labels

Flap Label +3: L Flap Label +2: +2 Flap Label +1: +1 Flap Label 0: +0 Flap Label -1: -0 Flap Label -2: -2 Flap Label -3: -S

In order to enable the display to be adapted to the labeling of the flaps in the cockpit, a label can be selected here for each flap position, named in the software from -3 to +3.

Each position can be chosen from a range of digits from -9 to +20 and letters such as N,L and S. Additional letters or numbers can be added on request. The labels on the flap lever can represent positions or degrees for the inclination of the flap, this varies from manufacturer to manufacturer.

For reasons of space, the plus sign is only displayed for digits less than 10. Negative values are supported up to -9 (so far sufficient for all models considered) and are always output with a minus sign.

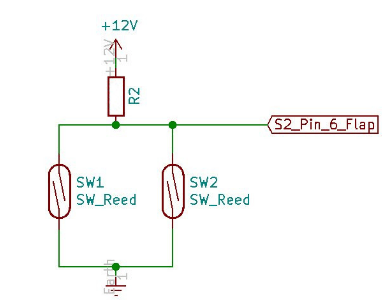

Flap Sensor

[Disable] [Enable IO-2] [Enable IO-34] [Enable IO-26]

This option activates the flap sensor, which was on IO-2 or IO-26 in earlier hardware versions and on IO-34 in later series. The settings for IO-2 or IO-26 can only be used together with the Bluetooth connection. With a WiFi connection, the use of the IO-34 is necessary, this will be supported from the second series in 2021. The display is made using the rectangle, which symbolizes the flap lever. The color of the rectangle changes depending on the position of the flap lever. With a good setting, shelf less than half a flap position, is the color green, otherwise white. In the case of a more serious error, more than a complete notch, the symbol also flashes in color red.

Sensor Calibration

[Cancel] [Start Calibration]

With the help of the flap sensor calibration, the flap sensor is measured for the latched flap positions. With [Start Calibration] the dialog begins, which prompts specified positions to snap. The dialog looks like this:

Set Flap +2 Sensor: 385 Saved

and thus prompts the flap position to be set to +2. The digitized sensor data in the range from 0..4095 are displayed in real time. If the flap is set correctly, the value is saved by pressing the push button and the next flap position is reached. At the end, the completion message “Saved” appears and the calibration is complete. The graphics for the flap display should then be checked. The flap positions must now match the selected flap position.

If this does not fit, e.g. because a position was not locked correctly, the calibration can be repeated at any time. If there are further problems, the installation of the potentiometer should be checked with a multimeter, for example. It is recommended that the potentiometer is installed in such a way, for mechanics see the section on the flap sensor below, that positive flap positions result in smaller resistance or digital measured values and negative positions result in larger values, so that a uniform procedure is used to check, measure and Facilitating support also works the other way around.

The values are proportional to the resistance of the potentiometer. If a separate potentiometer is used, it must be supplied with a voltage of 1.2V on one side; the input has no internal pull-up. In the simplest case, a resistor to the vehicle electrical system is sufficient. A regulated voltage is better.

It is recommended to use the XCVario flap sensor ( https://xcvario.com/product/flap-sensor/ ), which is now available and offered in the XCVario Shop, which works with a regulated reference voltage and an operational amplifier (voltage follower), and is therefore somewhat more precise works as a simple potentiometer, exhausts the full range and resolution of the AD converter, and delivers its voltage independent of vehicle electrical system fluctuations.

FLARM

FLARM

Alarm Level

[Disable] [Level 1] [Level 2] [Level 3]

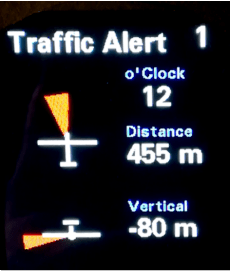

The variometer display is of secondary importance when a collision is imminent. When a FLARM is connected, the device can therefore be used to implement an acoustic and optical FLARM warning, similar to the common LED FLARM secondary display with a higher level of detail and additional information. The default is [Level 1], the FLARM warning is switched on at level 1 and informs you from the lowest alarm level “1” of the FLARM in the event of an impending collision in 13 to 18 seconds, level 2 would warn at 9-12 seconds, corresponding to level 3 only from the highest alert level, i.e. the immediate danger of a collision, between 0 and 8 seconds. Please refer to the description of the FLARM used for further details.

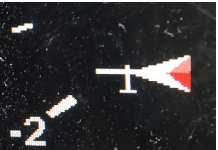

The warning is given on its own screen, which graphically in the form of a red triangle informs about the direction from which the danger is coming, both in the top view and in the horizontal view. An example of a Traffic Alert Alert level 1, the lowest alert level, see right. The danger comes from the front slightly to the left, shown here is a relative bearing of -10 degrees, so the red triangle shows the exact angle, analogously to the horizontal view. Furthermore, the type of warning and the alarm level is output by means of text, e.g. with “Traffic Alert 2”. The direction of approach in the clockwise system, e.g. “2 o’clock”, the relative distance and the relative altitude difference in the selected unit system.

Alarm Volume

[100 %]

The audible warning is designed as a constant and rapidly alternating two-tone tone to distinguish it from other tones and increases in frequency, tone sequence and volume according to the alarm level. In the highest alarm level 3, the warning tone is output with the level set here. At alarm level 2, the noise is reduced by around 6 decibels, at alarm level 1 by around 12 decibels. The default is 100%, the volume can be varied between 20% and 125%.

Alarm Timeout

5 sec

Configure here the time FLARM alarm warning keeps displayed after the Flarm alarm went off. Default is 5 seconds, together with the time the alarm is present this is normally enough time to read the and interpret the display. For feature testing and other purposes a longer time might be appropriate, and in competition even a shorter time may make sense, e.g. when circling in a lift with many other gliders.

FLARM Simulation

[Disable] [Start Sim]

The simulation of an approach by a second aircraft can be simulated under this menu item. The approach begins to the left below and moves to the right, with a further decrease in distance and height difference, past the bow. Different alarm levels of the FLARM are simulated optically and acoustically. The setup must be exited in order to be able to follow the situation on the screen.

Compass/Wind

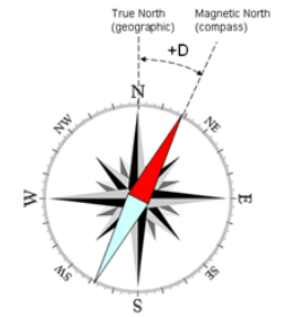

Compass/Wind

Compass

The compass is an optional module for the S2 interface, a magnetic sensor of the latest design, which allows an accuracy of up to one degree deviation with an optimal installation position and calibration. The magnetic sensor measures the earth’s magnetic field in 3D, i.e. in all 3 spatial directions, and has a tilt angle correction (tilt compensation). The sensor gets the inclination data from the AHRS module. For this it is necessary that the sensor calibration of the AHRS sensor is carried out once in its installation position, preferably in flight attitude. It is not necessary to activate the AHRS feature.

The magnetic sensor must be firmly connected to the aircraft in the correct position, the symbolism on the sensor shows an aircraft symbol with tail and wings, this must match the real aircraft and the lettering ‘Top’ must point upwards. There must not be any metal in the vicinity at the installation site, 20 better than 30 cm distance are minimum distances to deliver good results. The compass should not show more than 15°, better only 10° deviation (deviation) in any direction. A good position in a narrow glider fuselage, self-launchers or two seaters with lots of controls, cables and steel parts and various fittings is not easy to find. The cable should not be longer than two meters and should be point-to-point. If a flap sensor is also installed, pins 3 and 4 on interface S2 must only run to the magnetic sensor. Do not use an Y-Piece for an optional flap sensor but the S2-Extender if you got both. Otherwise, reading errors and even failure of the compass are possible.

For reasons of space, the display of the magnetic heading is currently only supported in the retro display or the UL style.

In the following menu items, its settings as well as the calibration of the sensor or the compensation of the deviation can be carried out.

Sensor Option

[Disable] [Enable I2C] [Enable I2C no Tilt Comp.] [Enable CAN Sensor]

With this, the type of magnetic sensor can be selected or the sensor can be switched off. By default, the magnetic sensor is switched off [Disable]. In the [Enable I2C] setting, a simple magnetic sensor connected to S2 with an I2C interface is selected, which compensates for the tilt angle (English Tilt Compensation). In the setting without tilt compensation in the next point, the usual compass rotation error up to an inversion of the display values can be expected. This setting is essentially only for test purposes, e.g. for a test setup on the top of a car. The [Enable CAN Sensor] setting enables the use of a new magnet sensor type with CAN interface as well with tilt compensation, which means that the serial interface on S2 remains free and can be used for other purposes, e.g. for the serial connection to an OpenVario. Furthermore, there is no restriction on the cable length for the CAN interface (max. 2 meters with I2C), the CAN magnetic sensor can therefore be installed at any point.

Note CAN: When selecting the CAN type, the CAN interface must be switched on in the system menu, the setting 1000 Kbit is recommended, other data rates are also possible. The sensor should also be plugged in when the compass is switched on, otherwise the software will query the module regularly, which will generate unnecessary CPU load in the event of an error.

Sensor Calibration

[Cancel] [Start] [Show] [Show Raw Data]

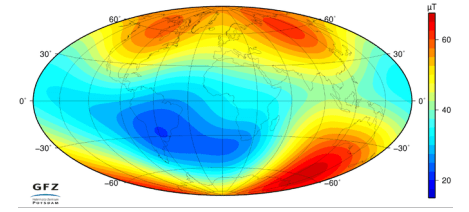

With this option, the measuring range of the magnetic sensor is calibrated in the same way as you know it from the compass module of a mobile phone. The calibration must be carried out again if the strength of the earth’s magnetic field changes, this is the case, for example, if you move to a different region on the globe. Normally, it is sufficient to carry out the calibration once.

For the purpose of calibration, the sensor must be swiveled in all spatial directions, which must be done before the sensor is permanently installed in its installation position at a location that is as free of metal or magnets as possible. The minima and maxima of the magnetic field strength in the individual spatial directions X,Y,Z are recorded and permanently stored in the non-volatile memory of the XCVario. Calibration is complete when the three displayed scale values (X, Y, Z scale) are close together and no longer change. In the sensor dialog, the measured field strength for the individual directions X,Y,Z is displayed live as a percentage of the maximum value of 2 gauss to the right of the scaling value in brackets.

example:

X Scale=95.2 (-5.2) Y-Scale=100.4 (3.9) Z-Scale=102.1 (13.9)

The best results are achieved if you calibrate the 3 directions individually and make sure that each direction X,Y,Z displays the maximum possible positive field strength once, e.g. (+18.5), and then and in the opposite direction, i.e. rotated 180 degrees, and with that the maximum negative display shows eg (-18.5). This is to be carried out for all 3 spatial directions in both directions. The corresponding spatial direction will turn green if the maximum values have been reached. This is the case when the other two directions are at zero or close to zero (display value less than 1.0), the other two direction sensors are then orthogonal to the earth’s magnetic field. A small graphic with maxima and minima, as well as the current measured values for the six directions X,Y,Z, positive and negative, makes calibration easier.

The X-axis of the sensor runs across the board (i.e. along the short side), the Y-axis along it (along the long side), and the Z-axis runs exactly perpendicular to the surface of the board.

Attention: The inclination, i.e. the inclination of the field line of the magnetic field to the earth’s surface, is between 62° and 70° in Germany (steeper in the north), the sensor for calibration is therefore at an angle of about 35°, namely inclined to the south, compared to the horizontal hold to capture the maximum value. Once you have found this, you rotate the sensor in exactly this position by 180° around its own axis, where this value is inverted. Then the sensor is rotated 90° in a different direction for the next axis.

The saved results of the calibration can be viewed at any time under the [Show] option.

With “Show Raw Data” the raw measured values, the sensor data, can be delivered in real time. An example is below:

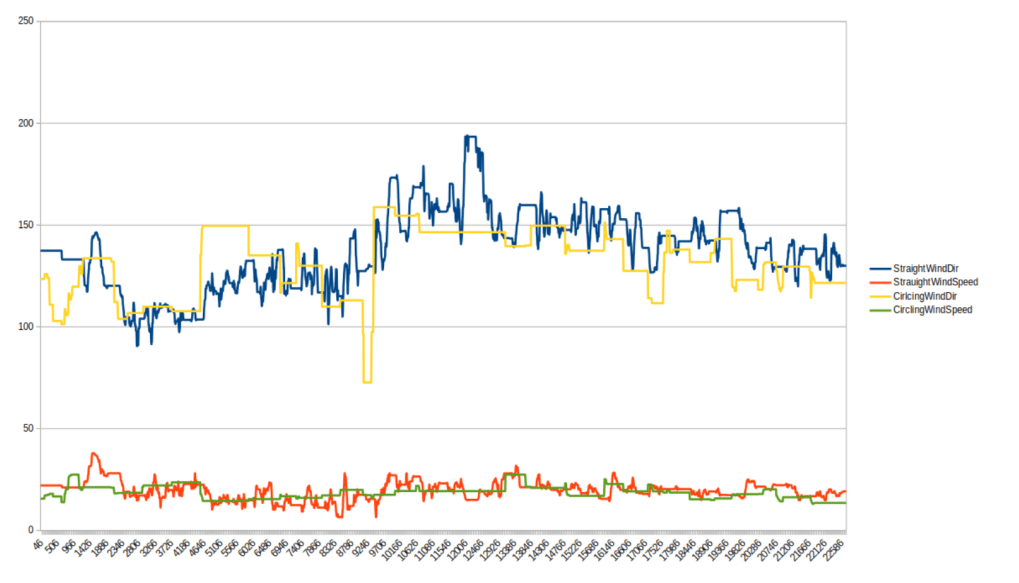

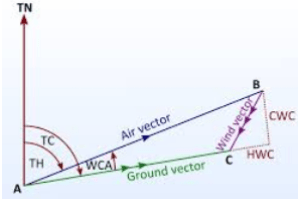

X = 3397 Y = 1874 Z = 5420 Raw magn H= 48.0 uT Cal magn H= 48.5 uT